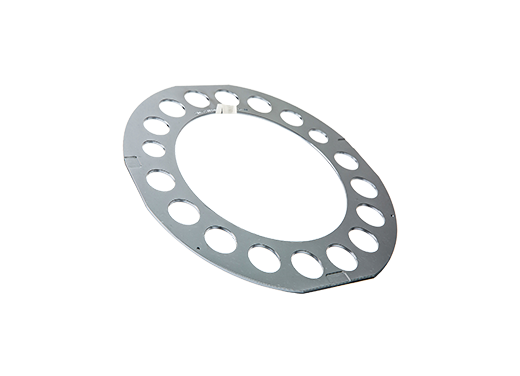

ferrotec series products: si fusion furnace ware and precision silicon parts

ferrotec (china) si fusionand si parts products provide ideal silicon furnace ware and silicon parts for etcher which helps improve metal contamination, reduce slip and particle. we focus on manufacturing silicon boats, pedestal and injectors for wafer high temperature process and lpcvd process. we also provide silicon focus rings and showerheads for etching process.